钢丝绳润滑器

应用Application:

本养护润滑系统广泛应用于船、闸、港口、码头、矿山等多场合钢丝绳设备,如牵引、起重、电梯、钻探、塔吊等。

The maintenance lubrication system is widely used in wire rope equipmentin many occasions, such as ships, gates, ports, wharves, mines, etc. And it is also widely used in traction, lifting, elevators, drilling, tower cranes and so on.

优点Advantage:

清洁无敌、高效安全、效率高于人工5倍以上,重量轻、安装方便、调节快捷、可确保钢丝缆绳充分润滑、穿透力强、无失效、延长钢丝绳使用寿命、节约维护成本。

Cleanliness, high efficiency, safety, efficiency is more than 5 times than manual, light weight, easy installation, fast adjustment, can ensure that the cable fully lubricated, strong penetration, no failure, extend the service life of wire rope, save maintenance costs.

工作原理Operational principle:

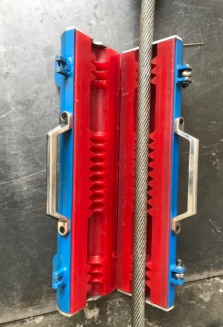

将润滑器夹持在钢丝绳上,并用两条松紧件固定。当钢丝绳运动时,每一段从润滑器中间通过,经过润滑器油脂腔。打开球阀,压缩气体进入,气动油脂泵将桶装润滑脂打出,经过高压油管注射到润滑器中,高压油脂能够穿透钢丝绳,对钢丝绳进行充分润滑,并在表面涂上薄薄一层。供油量根据钢丝绳的粗细和运行速度计算,可以很方便的通过控制阀进行调节,这样既保证了钢丝绳的充分润滑,也确保润滑脂不会浪费,是科学、安全、经济、高效、适用的润滑方法。

The lubricator is clamped on the wire rope and fixed with two elastic parts.

When the wire rope moves, each passage passes through the lubricator and passes through the grease cavity of the lubricator.Then open the ball valve, and compressed gas enters, pneumatic grease pump will beat out the barreled grease and injection into the lubricator through the high-pressure oil pipe. The high pressure grease can penetrate the wire rope, lubricate the wire rope sufficiently, and coat the surface with a thin layer. According to the wire rope's thickness and running speed, the oil supply can be adjusted conveniently by the control valve. This not only ensures the full lubrication of the wire rope, but also ensures that the grease will not be wasted. It is a scientific, safe, economic, efficient and applicable lubrication method.

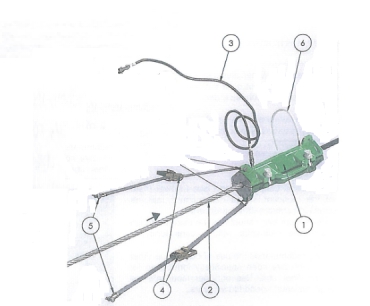

系统构成System configuration:

序号NO. | 名称(NAME) | 数量(QTY) |

1 | 润滑器 WIRE ROPE LUBRECATOR | 1 |

2 | 快速连接高压输油软管 HIGH PRESSURE DELIVERY HOSE WITH FEMALE QUICK CONNETCS | 1 |

3 | 排油脂软管 CLEAR LUBRICANT DRAIN HOSE | 1 |

4 | 棘轮张紧带 RATCHET TIGHTENING BELT | 2 |

5 | 弓形卸扣 BOW SHACKLE | 4 |

6 | 电动油脂泵 GREASE PUMP POWERED BY AIR PRESSURE | 1 |

7 | 油脂箱重力压盖 GRAVITATIONAL PRESSURE CAP OF GREASE BOX | 1 |

Assembly @ Operation Manual

安装及使用方法Installation and usage

1、打开包装,再打开储油桶的锁扣,将桶盖倾斜把桶内的压油盘拉出。Opened the package, and then open the lock oil drum, the pressure within the barrel tilt the barrel oil pan out.

2、 把储油桶底的大小孔对准推车机箱上的桶底安装板上的螺孔,用所配的螺钉将其连

接好。Storage in the bottom of the large holes on the trolley case on the bottom of the barrel to install screw holes on the plate, matched with the screw will be connected

3、 将所要加注油料放进储油桶内,将配的压油盘的桶盖将油压实,并压紧桶盖,合上

铺扣。Will have to refill oil into the storage barrel, will match the pressure of the oil pan lid will oil pressure, and pressure barrel cover, close the shop.

4、启动机盖上的绿色按钮,电机启动,打开注油枪的扳机,开始注油作业。一般将调压开关调至30-35Mpa,便可正常使用,最高调至35Mpa.压力调节的方法:

Start the machine cover on the green button, the motor start, open the oil gun trigger, start filling operations.

General dispatch switches to 30-35 mpa, can be normal use, to 35 mpa. The highest pressure regulating methods:

(1) 压力调节器上有一旋钮,旋钮上有一刻度指示线,旋钮可以顺时针和逆时针旋

转(箭头指示其大小方向),这样就可以调节输油压力,压力调节器上有一压力刻度线,一般压力调节在72-160的刻度,压力指示表上指针应在100-160公斤。最大不能超过 178 的刻度。There is a knob on the pressure regulator, a scale on the knob lines, knob clockwise and counterclockwise (arrows point to the direction of its size), so that it can regulate oil pressure, there is a pressure on the pressure regulator scale line, general pressure regulation in the scale of 72-160, on the pressure indicator pointer should be 100-160 kg.

But not more than 178 largest scale.

(2)在注油的过程中,压力表的指针指向最大值,这表明加油口压力超过了输油压

力,应马上关掉电源,停止注油。In the process of filling, pressure gauge pointer to a maximum, which suggests that filler pressure than the oil pressure, should immediately turn off the power and stop the oil.

(3) 当加油完毕时,注油枪的扳机关闭,电机会自动停止工作,如果不停止,表面

按钮刻度指示线过大,应逆时针旋转,把压力调小,再关闭电源。When finished refueling, oil gun trigger off, electric opportunity to stop working automatically, if not stopped, the surface scale button indicator is too large, should be counterclockwise, put it down, then turn the power off.

5、 停止作业,当您作业完毕时,关闭机壳上的红色按钮即可切断电源。Stop operation, when finished your homework, close the chassis on the red button to switch off the electricity.

设备保养与注意事项: Equipment maintenance and matters needing attention:

对设备进行适当的保养工作,使设备经常保持良好状态是延长设备使用寿命,保证使用高效率的必要手段。设备保养需要注意以几下点: Proper maintenance of equipment, make the equipment in good condition is often prolong the service life of equipment, the essential means to ensure the high efficiency of use.

Equipment maintenance at a few points to note:

1、本设备属于高压带电产品,请使用时按规定操作,使用电路中要安装漏电保护器,并

做好接地线,以免发生意外情况。设备的电源插头及电源线注意不要损坏,防止漏电事故的发生。This equipment belong to high voltage electric product, please use the operation by the regulation, used to install the leakage protector in the circuit, and make the grounding line, to avoid some accidents happen.

Equipment of the power plug and power cord be careful not to damage, prevent leakage accidents

2、减速器必须加注N220润滑油,至油标中心位置,每使用500小时以后,拆下推车后

盖,旋下加速器上的塑料螺母,更换机壳内的润滑油,经常检查减速器是否缺油,并及时补给,防止减速器缺油磨损。Reducer must refill N220 lubricating oil, oil to the center position, each with 500 hours later, remove the cart back cover, unscrew the plastic nut on the accelerator, replace the oil inside the casing, check whether the gear reducer is often lack of oil, and replenishment in time, prevent wear reducer is short of oil.

3、在不加注油脂时,尽量关闭电动机。否则长时间在高压下未卸压情况会对机器造成

一定的损害。When not filling grease, try to shut down the motor.

Otherwise under high pressure for a long time without pressure relief will cause some damage to the machine

4、高压软管在使用时不允许强力弯曲及受重物碾压以免损坏。不工作休息时应扣动注

油枪扳机排油,使设备内油压降低,以延长高压软管的使用寿命。High pressure hose when use do not allow the strong bending and heavy roller compaction in order to avoid damage.

Does not work when resting should pull the grease gun trigger discharge of oil, lower the equipment within the oil pressure, to prolong the service life of high pressure hose.

5在拆修过程中,零件应按次序轻拿轻放,避免损坏被拆零件的精度,保证零件表面

不被碰伤,确保安装后机器正常工作。In the process of repairing, the parts should be put in order light with light, avoid damaging the precision of the broken parts, ensure parts surface will not be damaged, ensure machine work properly after installation.

6、切勿当储油筒内油料不足时长时间空载开机,以避免柱塞油泵发热而损坏零部件。Don't lack of oil in the oil storage cylinder length no-load boot time, in order to avoid plunger pump heating and damaged parts.

7、平时要经常做好清洁保养工作,定期清洗整个油路系统,将注油嘴拆下油嘴,用清

洁机清洗冲涮管道中的杂物,并保持储油筒内油料的清洁。At ordinary times often should do a good job cleaning and maintenance, regular cleaning the oil system, oil gun will be removed nozzle, clean with clean machine washing pipes of sundry, and keep the oil storage cylinder oil clean.

8、改设备高压泵下端拉杆密封处有聚氨酯“U”型轴用密封圈一只,起到密封高压

泵的下腔的作用,磨损后会造成漏油,会使输出压力降低,要及时更换“U”型轴用密封。Change equipment high-pressure pump bottom rod seal has a "U" type polyurethane shaft with sealing ring a, have the effect of seal high-pressure pump inferior vena, will cause the oil after wear, will lower the output pressure, to replace with "U" type shaft seal in time.